Please note: Our texts are translated automatically. Errors may occur during this process.

Source: TWIKE press release 09.03.2023

With the order for the production of the first pre-series chassis components, the innovative TWIKE 5 three-wheeled electric vehicle is approaching another important step towards series production readiness. The bold investment comes at the end of intensive development work.

Almost four years to the day after the first presentation of the prototype at the Geneva Motor Show in March 2019 and two years after the start of series development, the makers of the TWIKE 5 are entering the next project phase.

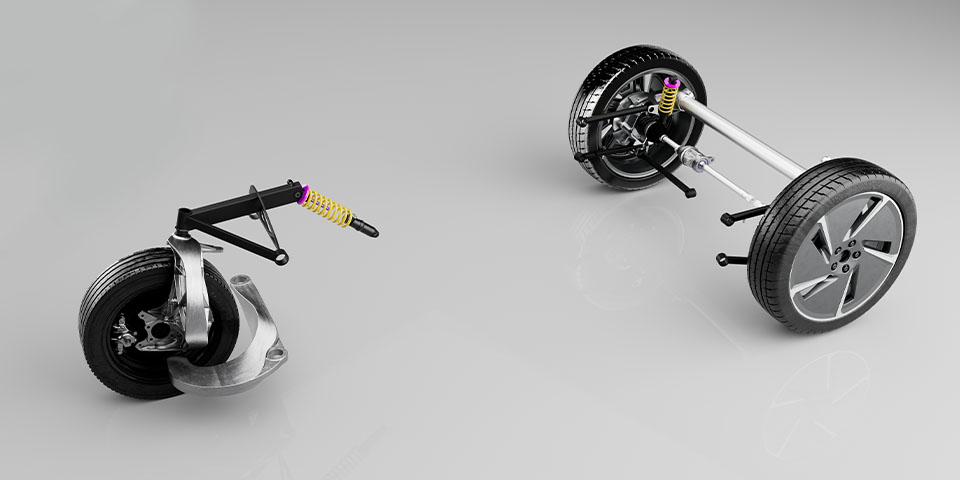

The order for wheel carriers, bearings, brake parts, suspension struts and wheels lays the foundations for completion of the pilot series for the 500 units of the TWIKE 5.

The story of the TWIKE 5 already began with the realization of the TWIKE 4. Conceived as a pure prototype and awarded the Automotive-X-Prize, the vehicle laid the foundation for the development of the TWIKE 5, which has since been continuously refined, improved and adapted to new requirements.

“After thorough, careful and repeated review and validation, the

chassis development has now reached the point where we can justify the necessary investment,” explains Martin Möscheid, Managing Director of TWIKE GmbH from Rosenthal in Hesse. “We wanted to have all influences secured in detail and not risk an unnecessary development loop out of recklessness or excessive impatience.”

For the development TWIKE engaged the renowned expert for automotive engineering Dr. Axel Pauly. The former technical director of the VW development company IAV and the person responsible for function integration and safety control systems at BMW provided significant support in improving safety and driving dynamics. Pauly focused here on optimizing the tricycle with the help of a newly developed camber-active rear axle. The task included not only the load-bearing parts, but all elements transmitting the driving forces, from the drive shafts to bearings and rubber elements to rims and tires.

The chassis parts now commissioned are partly developed in-house and partly borrowed from large-scale production. They give the generously powered three-wheeler with its low center of gravity the agility and driving stability of a four-wheeled sports car. TWIKE also relies on the support of experienced suppliers and service providers such as A-CONCEPTS, Borbet, Continental and KW automotive.

“Together with our partners, we are approaching the finish line with the TWIKE 5,” Möscheid explains. “We are now hoping for normalized delivery times so that we can enter driver testing as early as possible and subsequently issue a production release.”