Please note: Our texts are translated automatically. Errors may occur during this process.

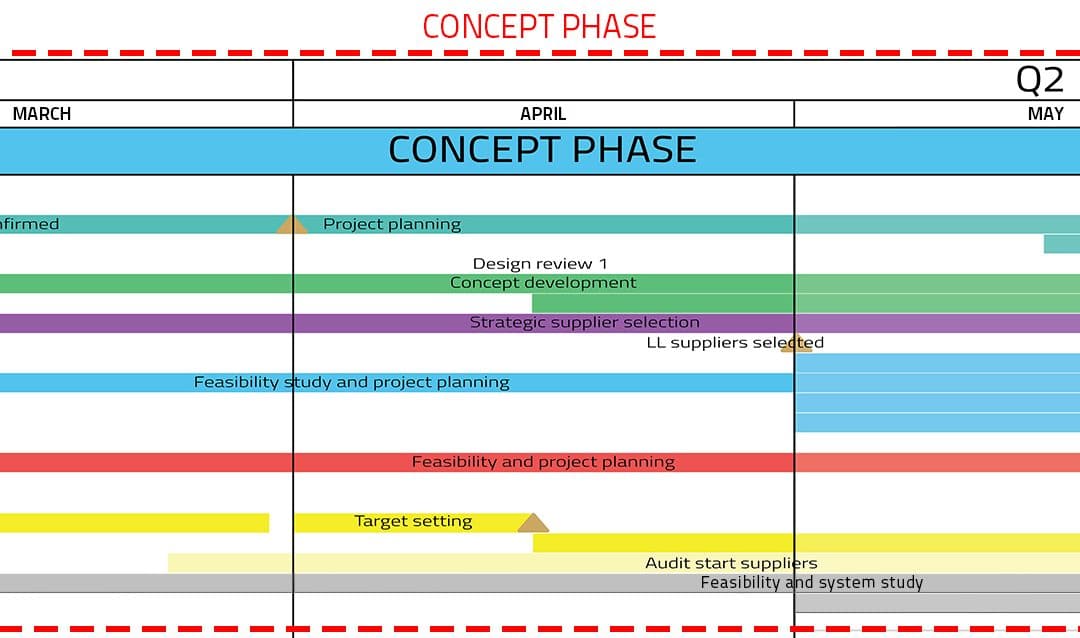

And already we are in the middle of it. In the concept phase of the TWIKE 5, even though all the components had somehow already existed, we had looked at every part three times from all sides. Now, taking into account all the specifications from the previous definition phase, all the components have to be defined again, given their final names, assigned a unique space in the CAD system and, at the same time, the manufacturability and assemblability must be consistently ensured, taking into account a more tightly scheduled series. At the end of this phase, both the total weight and the center of gravity position of the complete vehicle will have been confirmed. At this stage, the resulting frame structure is already sufficiently meshed to perform initial strength tests using a relevant CAE system.

On the one hand, the concept phase is dreaded because subsequent change requests are hardly possible. Because supposedly small changes could result in time-consuming and cost-intensive loops and set us far back in the schedule. In the concept phase, therefore, every decision for a component, its positioning or also the determination of the manufacturing method must be weighed up carefully with sufficient foresight.

However, the concept phase is also a grateful phase because the “concept freeze” at the end of this phase creates the necessary security and clarity for the following work packages. From the customer’s point of view, the processing of the so-called LOP (list of open points) is not very exciting, since it mostly involves the comparison of material and spatial data, positions of components, definition of connection types or sealing surfaces.

The fact that we are proceeding here with a high degree of development reliability and the corresponding manpower is largely due to the cooperation with the two experienced automotive service providers EDAG from Fulda in Hesse and the automotive developer VALMET Automotive, which is well-known in the scene. Both impose on us a tightly timed framework and the strict consideration of all solutions through the “series glasses”. The required higher series capability leads to a repeated run through of all necessary process steps (therefore concept phase reloaded). However, the cooperation brings exactly the quality into the TWIKE 5, which will sustainably ensure an impressive driving experience for the pilots.

Updates to follow.