Please note: Our texts are translated automatically. Errors may occur during this process.

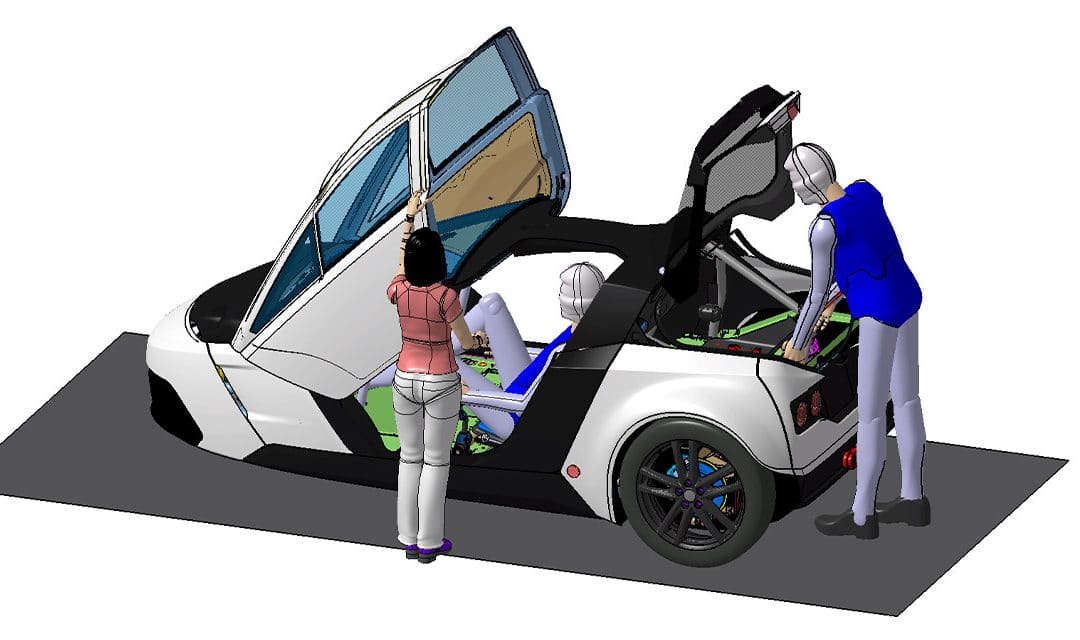

Please get in once and check the seating position. Can the hood be opened and closed from the outside even by a 5-percentile woman with a height of just under 1.53 m? Doesn’t a 95-percentile man bump his head on the tailgate even if he’s over 6’1″? Can they both find a sitting position in which they can ergonomically reach all the controls and optimally look out of all the glazing?

All these questions have already been taken as a basis for the design and must be checked several times during the transition to series production. All the adjustments leading to the series thus represent a constant balancing act, which the development team is mastering ever more finely, however, and which represents a great quality in the project.

The difference to conventional vehicles is not only the specific ergonomics due to the pedaling in the TWIKE. The ergonomic conditions from assembly and subsequent service processes are also taken as a basis. The BIW (body in white), which sums up everything in the deeper core of the vehicle, should not be touched later, even in service.

The connection of all components, especially the attachment points of all moving components (chassis, hinges, hood dampers) must also be sufficiently secured to avoid unnecessary costly loops. The preparatory work for the last development loop of the BIW for the time being was readjusted and reviewed. The result of this loop will be the set of drawings for an assembly-ready body shell that is as lightweight and crash-optimized as possible. The production method selected is suitable for small series production and allows the first samples for the driver test vehicle to be produced once the loop has been completed.