Please note: Our texts are translated automatically. Errors may occur during this process.

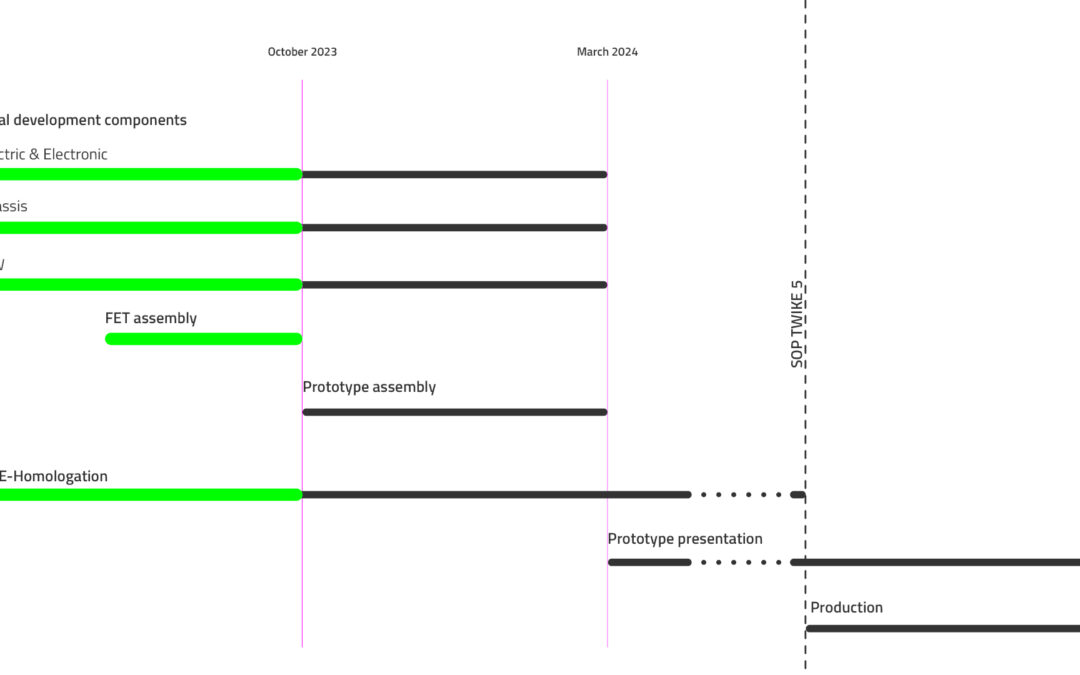

A number of milestones on the roadmap still need to be ticked off before TWIKE can get started with production. Work has already begun on setting up the warehouses and workstations for preliminary and final assembly required for the production steps to be completed in Rosenthal. The next steps are as follows:

Finished development of all components

Conceptually, the development is complete. Also, more than 95 percent of the TWIKE 5’s components are sufficiently designated for procurement. Larger components that require final reworking for series production include the frame structure at the rear, the steering system and some chassis components that require tooling. We were able to complete this process for FET at the beginning of October.

Structure of driver test carrier (FET)

In order for the newly developed vehicle to meet the requirements of safe driving dynamics, various tests and any optimizations on driver test vehicles are required. By this we mean prototypes which are roadworthy but do not yet necessarily have a fairing. The FET was built and testing could be started in October.

Prototypes

As soon as the driver tests have been positively completed and the frame (BIW), chassis and powertrain are deemed approvable by us and the accompanying experts, we can add the exterior to the driver test vehicles and thus build fully-fledged prototypes. We will present these prototypes to our customers and at the same time carry out final physical tests for ECE homologation. According to current estimates, these prototypes may be available in March 2024.

ECE homologation

As soon as the driver tests have been positively completed and the frame (BIW), chassis and drive system have been approved by us and the accompanying homologation is the technical term for the type approval of a vehicle, or the approval of a series vehicle in the EU, which is also accepted by some non-European countries. For this purpose, we work together with the Luxembourg approval service provider ATEEL. The Kraftfahrt-Bundesamt (Federal Motor Transport Authority) in Flensburg confirms the completeness of the required evidence and subsequently issues the EU approval.

Converting the pre-order into order

With the inspection of the prototypes, customers are given the opportunity to convert their pre-order into a binding order. This will be the final lever for the start of series production.

Once the starting signal has been given, two vehicles a day are to be assembled at the Rosenthal plant once production processes have been ramped up. We continue to assume that we will be able to reach this point in mid-2024. Within a period of twelve months, starting after SOP and reaching the so-called ridge line of production of two vehicles per working day, the planned 500 TWIKE 5 will then be produced and handed over to our customers.

In order to be able to keep to the ambitious schedule, it is essential to have sufficient liquidity at all times. Delayed access to the required funds will delay the schedule. In our opinion, however, the presentation of prototypes at the latest will dispel the current reluctance to make advance payments.

Since we were not able to cover 100 percent of our capital requirements until the start of deliveries via crowdfunding, we are now closing the gap via down payments. Our interest-based ranking system allows later pre-orderers to move up in the ranking with a higher down payment and also to reserve a desired serial number.

Post updated 10/16/2023

You can find out how our reservation system works here.